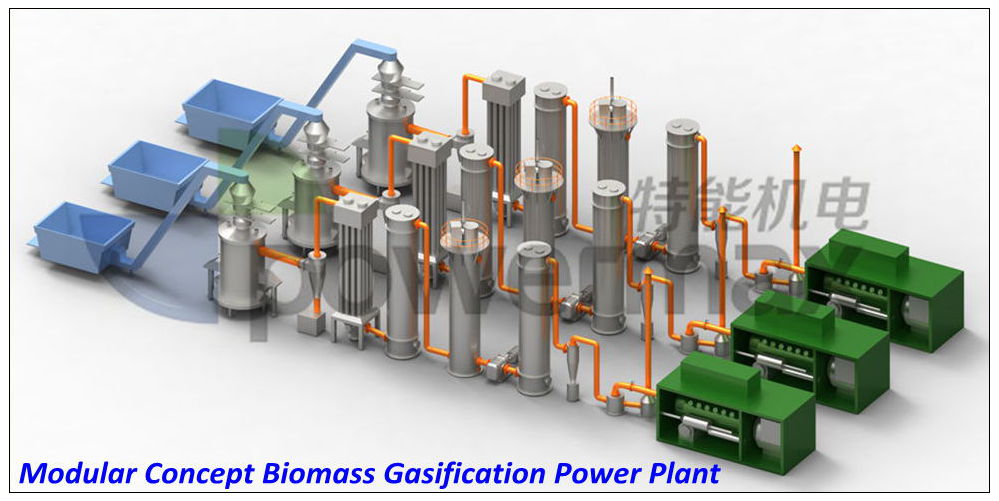

1. Biomass Storage

2. Biomass Conveyor

3. Biomass Buffer Bin

4. Biomass Gasifier

5. Cyclone Dust Collector

6. Gas Filter

7. ESP

8. Gas Scrubber

9. Gas Dryer

10. Blower

11. Buffer Tank

12. Gas Flare

13 Gas Generator Sets

Office Address:4th floor, Chuangrong Building Block C, Danshan Road, AnzhenStreet, Xishan District, Wuxi, Jiangsu, China.

Factory Address:No.26 Jingrui Rd, Xibei Town, Xishan District, Wuxi, Jiangsu, China.

Skype: tnjd168

Email:info@powermaxgasifiers.com

Email:sales@powermaxgasifiers.com

Mobile/WhatsApp: +86-13812083566

Tel:+86-510-68229610

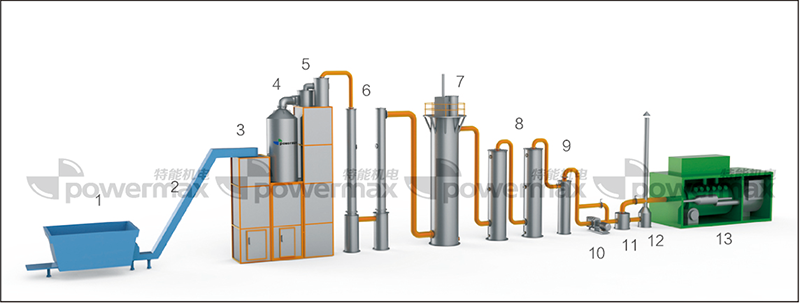

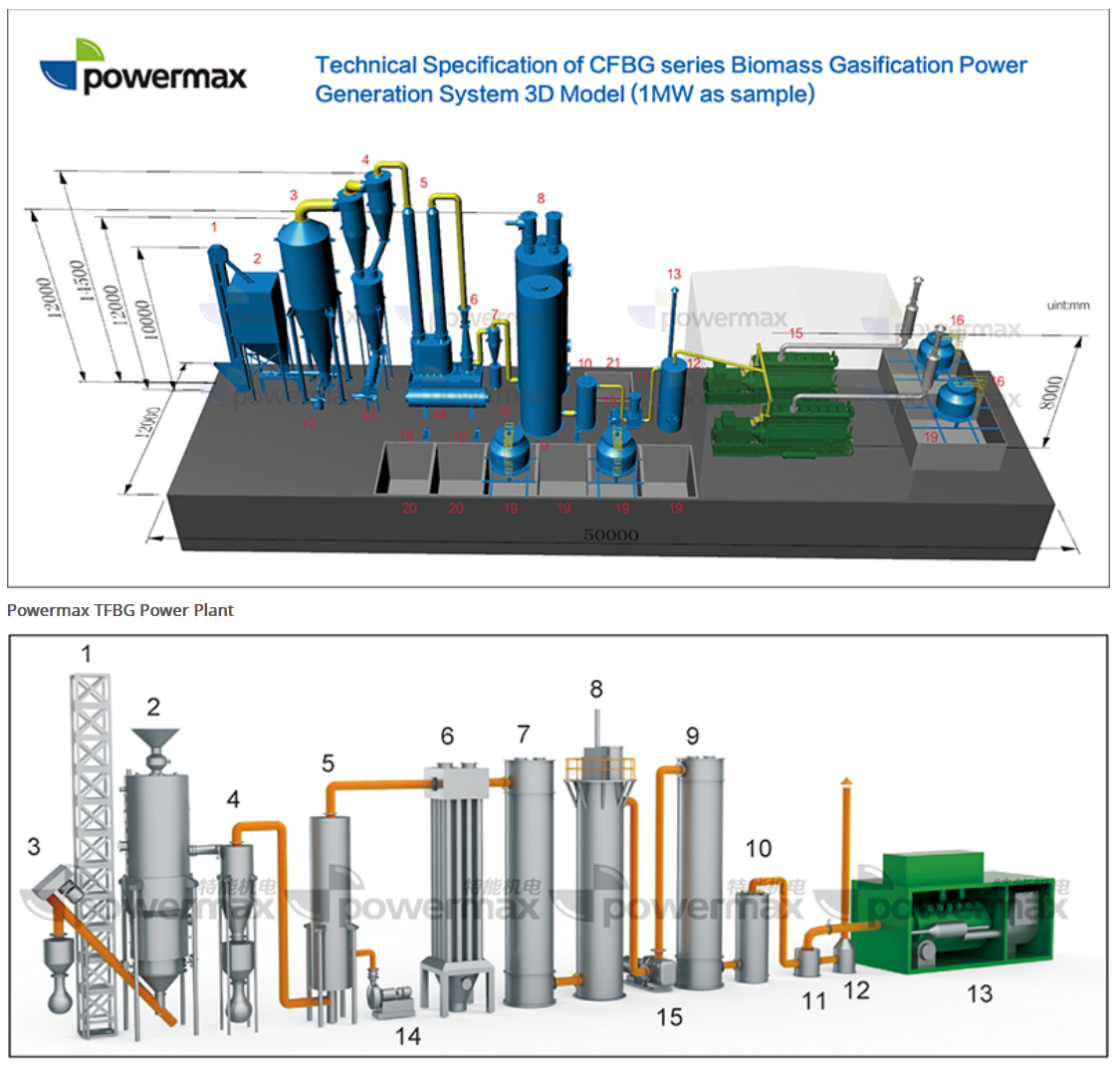

1. Biomass Storage

2. Biomass Conveyor

3. Biomass Buffer Bin

4. Biomass Gasifier

5. Cyclone Dust Collector

6. Gas Filter

7. ESP

8. Gas Scrubber

9. Gas Dryer

10. Blower

11. Buffer Tank

12. Gas Flare

13 Gas Generator Sets

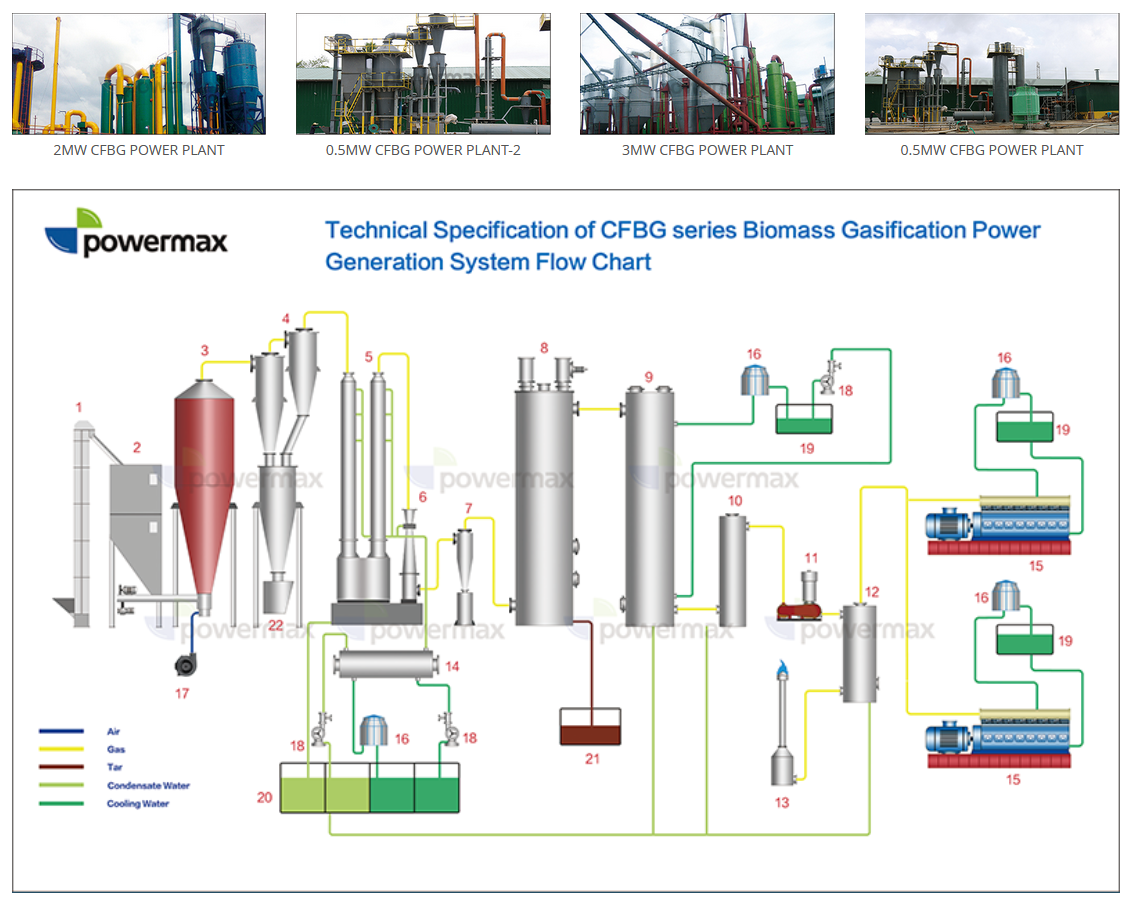

| Model | 200CFBG | 400CFBG | 500CFBG | 600CFBG | 800CFBG | 1000CFBG | 1200CFBG | 1500CFBG | 2000CFBG |

| Rated Power(kw) | 200 | 400 | 500 | 600 | 800 | 1000 | 1200 | 1500 | 2000 |

| Rated Frequency | 50 /60 HZ | ||||||||

| Rated Voltage(V) | 220 / 400 / 440 / 6300 / 6600 / 11000 /13800 | ||||||||

| Model of Gasifier | CFBG200 | CFBG400 | CFBG500 | CFBG600 | CFBG800 | CFBG1000 | CFBG1200 | CFBG1500 | CFBG2000 |

| Gasifier Type | Circulating Fluidized Bed Gasifier(CFBG) | ||||||||

| Biomass Moisture Requirement | ≤20%(wet basis) | ||||||||

| Biomass Size Requirment | ≤8-15mm | ||||||||

| Biomass Consumption(Kg/hr) | 200-360 | 400-720 | 500-900 | 600-1080 | 800-1440 | 1000-1800 | 1200-2160 | 1500-2700 | 2000-3600 |

| Gas Production(Nm3/h) | 500-600 | 1000-1200 | 1250-1500 | 1500-1800 | 2000-2400 | 2500-3000 | 3000-3600 | 3750-4500 | 5000-6000 |

| Ash Discharge Type | Dry Ash Type | ||||||||

| Type of Gas Purification | POWERMAX Semi Dry Type Gas Purification System | ||||||||

| Heat Value of Gas | 1200-1300Kcal/Nm3 | ||||||||

| Gas Composition | CO-12~18%, CO2-10~16%, CH4-4~8% H2-3~7% CnHm-1~1.4% O2-0.5~1.2% N2-54~60% | ||||||||

| Model of Gensent | 100GFLS | 400GFLS | 500GFLS | 300GFLS | 400GFLS | 1000GFLS | 400GFLS | 500GFLS | 1000GFLS |

| Qty of Genset | 2 | 1 | 1 | 2 | 2 | 1 | 3 | 3 | 2 |

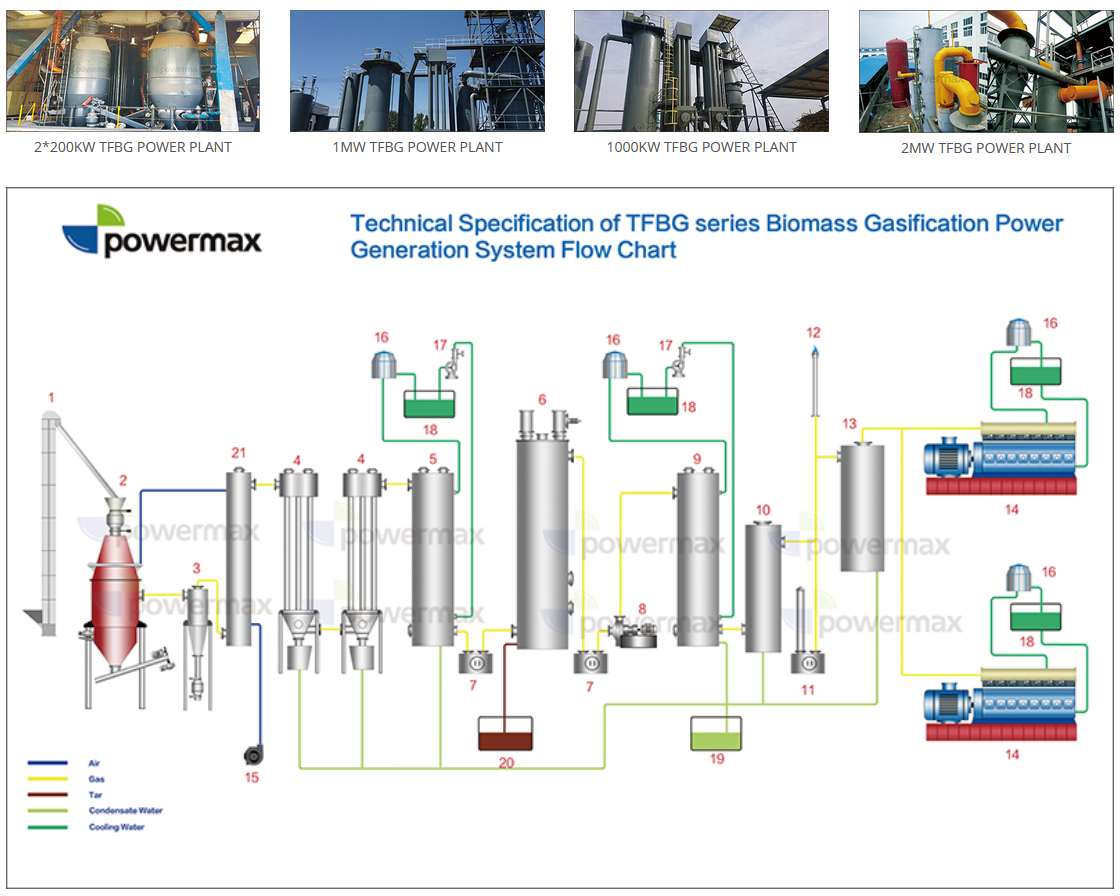

1.Elevator

2.Feed Bin

3.Gasifier

4.Cycloneer

5.Tube Type Dust Remover

6.Venturi

7.Cyclone Hydraulic Separators

8.ESP

9.Indirect Cooler

10.Water Drop Catcher

11.Roots Blower

12.Buffer Tank

13.Vent Cans&Gas Flare

14.Tubular Heat Exchanger

15.Gas Generator Set

16.Cooling Tower

17.Air Blower

18.Water Pump

19.Cooling Water Pool

20.Condensate Water Pool

21.Tar Tank

22.Biochar Outlet

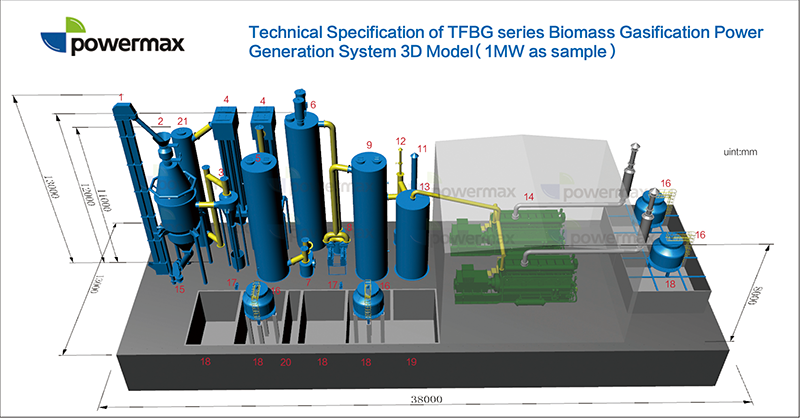

1. Skip Charger

2. Biomass Gasifier

3. Dry Ash Discharger

4. Cyclone Dust Collector

5. Hot Air Heat Exchanger

6. Air Cooler

7. Gas Cooler

8. ESP

9. Gas Cooler

10. Gas Dryer

11. Buffer Tank

12. Gas Flare

13. Gas Generator Sets

14. Blower

15. Gas Compressor

1.Elevator

2.Gasifier

3.Cyclone

4.Air Cooler

5.Indirect Cooler

6.ESP

7.Isolation Seal

8.Booster Fan

9.Indirect Cooler

10.Water Drop Catcher

11.Water Bleeding

12.Gas Flare

13.Buffer Tank

14.Gas Generator Set

15.Air Blower

16.Cooling Tower

17.Water Pump

18.Cooling Water Pooling

19.Condensate Water Pool

20.Tar Tank

21.Hot Air Heat Exchanger