Office Address:4th floor, Chuangrong Building Block C, Danshan Road, AnzhenStreet, Xishan District, Wuxi, Jiangsu, China.

Factory Address:No.26 Jingrui Rd, Xibei Town, Xishan District, Wuxi, Jiangsu, China.

Skype: tnjd168

Email:info@powermaxgasifiers.com

Email:sales@powermaxgasifiers.com

Mobile/WhatsApp: +86-13812083566

Tel:+86-510-68229610

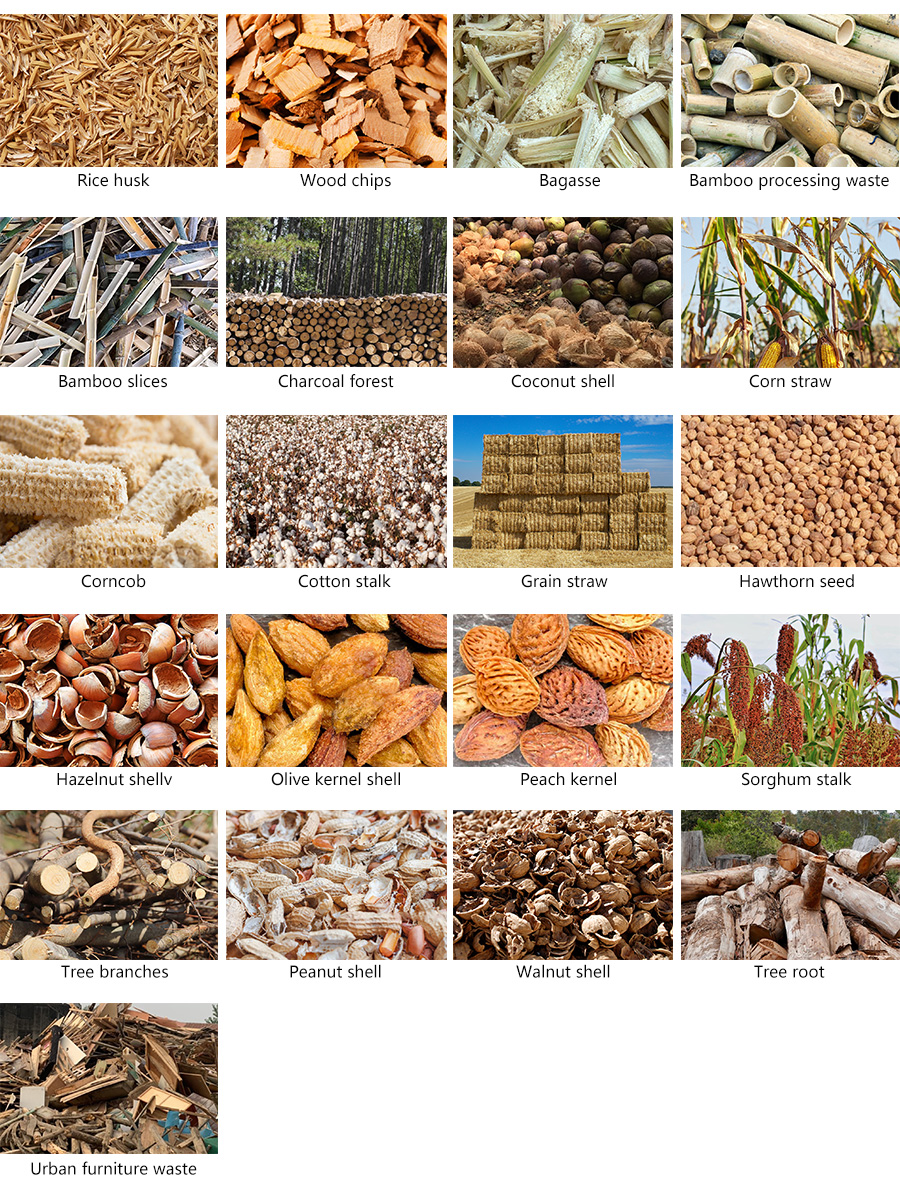

Biomass - Agri Residues

This Woody Biomass Gasifier can use different types of woody biomasses. The woody biomass to be used will need to be sized as per the specification of the specific rating of Gasifier model and the moisture content will need to be less than 20% in general.

Wide ratings are available right from 50 kgs/hr to 2,000 kgs/hr system. For higher ratings, multiple systems are offered.

Fine Biomass Gasifier can use different types of fine biomass, pellets, threshed agri residues etc.

The fine biomass to be used will need to be as per the defined specification with moisture content below 20% in general.

Charcoal Generator

This innovative technology results in simultaneous production of char / charcoal as well as a high quality Combustible gas that could be used for power generation or for a variety of thermal applications.

The charcoal yield is of the order of about 13% of biomass by weight.

The process totally eliminates any adverse environmental impact as no harmful vapours or particulates are released into the environment.

The overall energy efficiencies are extremely high (of the order of 80%) and thus, the biomass resource is almost fully utilized and converted to very high quality energy streams.

Most types of biomass can be used as feedstock with wide range of moisture contents acceptable to the systems.

The final particle size of char / charcoal is directly related to feed size and the system allows for a wide range of particle sizes to be used with char / charcoal output also being controllable as per the final requirement.

coal

Powermax offers a completely new process for gasifying coal. The systems uses a Downdraft process instead of the conventional updraft process. The updraft process (as is used) is one where the coal is fed into the gasifier from the top and the gas is also taken out from top. This leads to the gas entraining a lot of tar along with it as the gas needs to pass through the Pyrolysis zone where the tars come out. In the downdraft process on the other hand, the coal is fed from the top while the gas is taken out from the bottom. This leads to the gas being almost tar free.

Powermax Clean Coal Gasification Technology and benefits:

Systems need no steam and are in negative pressure.

This ensures that there are no pressure related issues or explosions. Thus much Safer.

A State-of-the-Art Dry Gas Cleaning Technology is used to cool and clean the gas, depending on the application.

Thus the systems are environmentally sound as not only do they not generate tars, but also because there is no water that directly comes in touch with the gas for cooling and cleaning (thus no process water is created).

The system is completely PLC controlled allowing for safeties leading to system alarms, shut downs etc.

Specification of Coal that can be used:

We are currently offering the Coal Gasifier with Indonesian Coal as per the following specifications:

Coal Grade - ‘B’ Grade

CV - ≥5500 kcal/kg on ADB

Sulphur - ≤1.5% by weight based on elemental or ultimate analysis

Volatile Matter as Dry Basis : 20%-30%

Moisture - Around 12 to 18% on wet basis

Ash Content - < 5 % on Dry basis @ Ash Melting Point. > 1100°C

Size - Between 20 mm to 80 mm or above

If there is any other types of Coal available in any region, the specs or some samples could be sent to us.

We can review and confirm the possibility of using it in our Coal Gasifier.

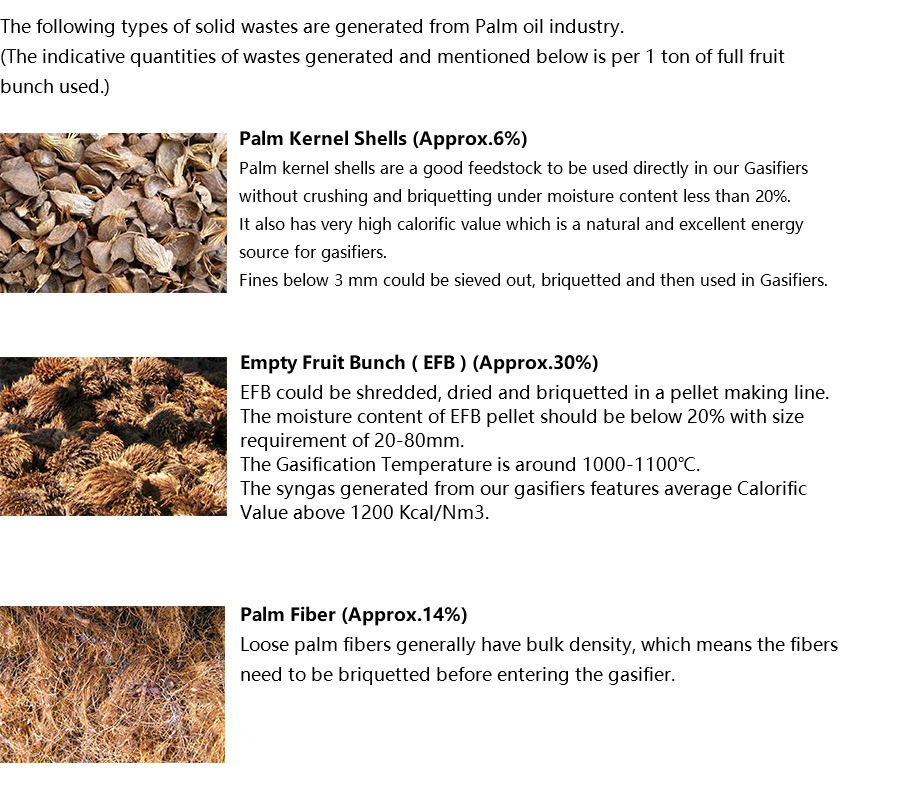

EFB

MSW- RDF

An innovative technology has been developed for processing MSW / RDF with minimal sorting / separation and with Maximum Energy Recovery.

This, we believe, promises to change MSW processing – to the extent that this major challenge could indeed become an opportunity.